Are you thinking about a turnkey interior Fitout solution n Dubai? Schedule a complimentary site survey with Build Craft Interiors in Dubai! You’ll receive a detailed program, a breakdown of costs, and sustainable options that fit your budget.

From design, approvals, procurement, construction, MEP, joinery, finishing, testing/commissioning, and post-handover support, a turnkey fit-out provides your space from conception to handover through a single responsible partner. You receive a single contract, a single schedule, a single budget, and a space that is operationally ready from day one.

1) Single-Point Accountability

Consider a single team handling all aspects of design, procurement, delivery, and cost planning. This method reduces the blame game, gaps, and variations. Because there is only one responsible party making the calls, problems are resolved swiftly.

We can significantly accelerate things by integrating design, involving suppliers early on, and implementing parallel workflows. This implies that offices, restaurants, and retail establishments can open earlier and begin making money more quickly.

Budgets are immediately compared to market prices when the same team handles both design and construction. Early value engineering reduces costs and helps avoid rework.

We observe fewer defects when we use factory-controlled joinery, pre-qualified subcontractors, and well-coordinated mechanical, electrical, and plumbing (MEP) work. Specifications, mock-ups, and on-site workmanship are all in sync thanks to a single system for quality assurance and control.

Clients save a great deal of time on coordination when a dedicated turnkey team handles all the drawings, health and safety, and authority submissions (such as civil defense and landlord requirements).

Enforcing material submittals (such as low-VOC and FSC timber), efficient lighting and HVAC systems, and waste management—all of which support LEED, WELL, and Estidama goals—is considerably simpler when a single contractor oversees the entire process.

One program, one risk register, and one change control procedure are visible to all parties. Timelines are maintained and disagreements are lessened thanks to this clarity.

Discovery & Brief: goals, brand, personnel, and functional relationships

Concept & Cost Plan: high-level BOQ, mood boards, layouts, and VE options

IFC drawings, MEP coordination, and landlord/authority compliance comprise the detailed design.

Procurement: verified vendors, long-term lead monitoring, and prototypes

HSE, QA/QC, progress reporting, and client walkthroughs in construction and fit-out

Soft landings, MEP balancing, life safety testing, commissioning, and snagging

O&M manuals, warranties, training, and post-occupancy support are all part of handover and aftercare.

Use Cases Where Turnkey Shines

Workplaces that require tech integration, acoustic privacy, and phased occupancy

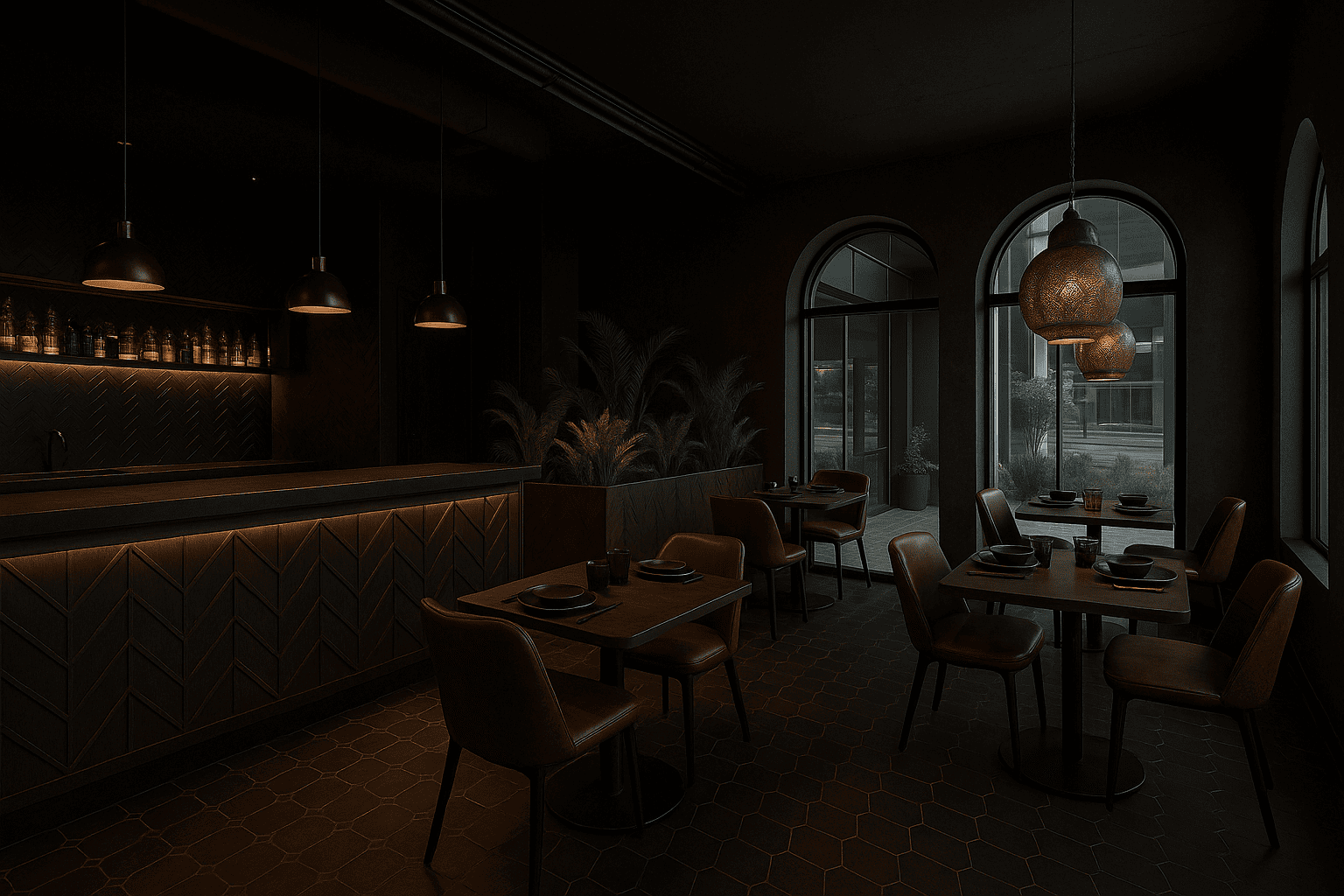

F&B/Retail, where quick roll-outs and brand standards are essential

High-end joinery and finishes in luxury and hospitality homes

Strict HSE/IAQ coordination is needed in healthcare and education.

Cost & Program: What to Expect

Budgeting: Low variation percentages are maintained by early cost plans that are in line with the design.

Program: Compared to separate contracts, parallel design-procurement-build typically results in shorter fit-out times.

Risk: By locking long-lead items earlier, integrated teams can lessen supply-chain shocks.

Sustainability & Wellness in Turnkey Delivery

Looking to create a healthier environment? Here’s what you need: Low-VOC paints and adhesives, boards that are free from formaldehyde, and carpets made from recycled materials.

For energy and lighting, consider using LED lights with smart controls, a task-ambient strategy, and plenty of natural daylight.

To improve indoor air quality, focus on good filtration systems, monitor CO₂ levels, and keep up with regular maintenance.

When it comes to waste, think about segregation, take-back programs, and circular options like modular partitions.

How to Choose the Right Turnkey Partner in Dubai

Portfolio Fit: Scalable and proven projects in your industry

EPDs, VOC certificates, and compliance records are required for submission.

Supply Chain: vetted subcontractors and internal joinery/MEP coordination

Experience with Approvals: Record of Landlord and Authority

Aftercare: Post-occupancy commissioning, SLAs, and warranties

Sample Client Journey (Office, 900–1,200 m²)

Weeks 1–3: Concept + Brief + Budget

Weeks 4–6: Mock-ups, landlord submission, and detailed design

Weeks 7–14: MEP, site work, completions, and testing

Week 15: Documentation, handover, and snag closure

Build Craft Interiors: Your Turnkey Advantage

Complete Delivery: Design, approvals, construction, joinery, MEP, FF&E

Speed and Quality: Accelerated programs with strict QA/QC

Sustainability: LEED/WELL-aligned low-emitting materials and effective systems

Transparent Reporting: Stakeholder dashboards for programs, costs, risks, and HSE

CTA: Are you planning a fit-out for 2025? To obtain a baseline program and phased cost plan, schedule a free consultation.

FAQ

We handle everything from concept design and approvals to procurement, construction, MEP, joinery, finishes, testing and commissioning, and finally, handover—all under one contract and one dedicated team.

Not usually. When we focus on early cost planning and incorporate value engineering, we can often minimize variations and lower lifecycle costs, all while speeding up delivery.

After drawings and long-lead items are locked, many offices can be accommodated in 12–16 weeks, depending on size and approvals. Complex scopes could take longer.

Clear program and cost reporting, a robust supply chain, a specialized portfolio, a proven history of authority approvals, and excellent aftercare.

A lot of people find that it makes getting approvals and keeping track of things much easier. A trustworthy turnkey contractor can quickly get on the same page with landlord guidelines.

Subscribe Our Newsletter

Quick Links

Services

Information

Phone : +971 52 831 2386

Whatsapp : +971 52 963 2272

info@buildcraftinteriors.com

projects@buildcraftinteriors.com

Dubai United Arab Emirates